Suscríbase a nuestro boletín y sea siempre el primero en enterarse de lo que está sucediendo.

Optoelectronic Sorting Tech Bring the Brighter Future of the Tungsten Resources Utilization

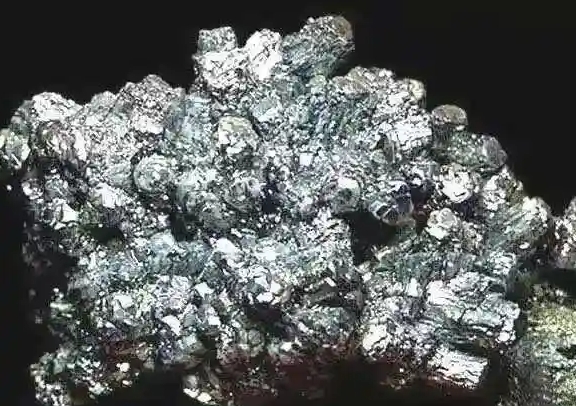

Apr 14, 2025Tungsten, as an "industrial tooth", is a strategic resource in fields such as aerospace, electronics, and military industry. The global distribution of tungsten resources is uneven, with China, Russia, Canada, and Vietnam being the main reserve countries, with China accounting for over 60%.

Although China has abundant tungsten reserves, it has long faced problems such as low mineral processing efficiency, complex associated processes, and tailings accumulation. How to achieve efficient utilization and green development of tungsten resources through technological innovation has become a focus of the industry.

一、The Disadvantages of Traditional Sorting Tech for Tungsten

Tungsten,incluing black tungsten and white tungsten.They all have complex mixed ore.The problems of traditional tungsten sorting tech not only the low efficiency,but also the complex relationships of ore features,tech road depending and environmental constraint.

The multi-scale embedding characteristics of tungsten ore (coarse-grained, fine-grained, and fine-grained coexistence) pose differentiated requirements for the process:

Due to its high density (7.1~7.5 g/cm ³), black tungsten ore can be processed by traditional gravity separation (shaking table, spiral chute) with a coarse particle size of+0.2 mm, but the recovery rate for fine particles of -0.074 mm is less than 40%;

The surface chemical properties of scheelite are similar to those of calcium minerals such as calcite and fluorite. Flotation requires highly selective collectors (such as fatty acids), but the reagent system is complex and can easily cause "mutual contamination of concentrates".

二、Optoelectronic Sorting Tech: a new Breakthrough for Tungsten Pre-sorting

The core value of optoelectronic sorting technology lies in the precise control of pre sorting of granular ores (-50mm~+5mm), reconstructing the logic of the mineral processing flow through "early waste disposal and early refining", and achieving rapid purification of ore value density at the source, laying a low consumption and high-efficiency foundation for subsequent fine-grained sorting.

In the traditional beneficiation process, the coarse crushed ore directly enters the grinding stage, resulting in excessive crushing of a large amount of low-grade waste rock, causing energy waste and metal loss. Optoelectronic sorting reconstructs the process of "crushing pre sorting grading treatment" to intelligently sort ores after coarse crushing (particle size -50mm), forming three major technological advantages:

Energy density optimization: Pre discard 30%~50% of waste rock, reducing the amount of ore entering the grinding process by 40% and reducing energy consumption per ton of ore by 15-20 kWh;

Metal flow enrichment: Increase the average grade of ore WO ∝ from 0.3% to 0.8% to 1.0% to 1.5%, and reduce the amount of subsequent flotation reagents by 20% to 30%;

Particle size protection: avoid fine sliming caused by waste rock over grinding (the content of -0.038mm decreases by 12%), and improve the stability of flotation foam.

三、Future Prospects: Intelligence and Full Industry Chain Cooperation

The promotion of optoelectronic sorting technology promotes the transformation of the tungsten industry towards a low-carbon and circular economy by constructing a full process system of "pre-sorting+deep recovery+tailings resource utilization" for tungsten ore.

From "rough sorting" to "intelligent fine selection", from "tailings landfill" to "turning stones into gold", the application of optoelectronic technology has not only improved the utilization rate of tungsten resources, but also reshaped the mining value chain.