Suscríbase a nuestro boletín y sea siempre el primero en enterarse de lo que está sucediendo.

Process flow of high purity quartz sand

Sep 27, 2024High-purity quartz sand refers to quartz powder with a SiO2 content of more than 99.99%, which is an important raw material for making quartz glass. This high-purity quartz sand is widely used in high-end industries such as integrated circuits, solar cells, optical fibers, lasers, aerospace and military.

So how is high-purity quartz sand extracted?

First of all, material selection is the key: quartz stone with a silicon dioxide content of not less than 99.3% is selected as the raw material. After cleaning and removing impurities, the raw material is crushed into 5-15mm particles with a crusher.

Next is the calcination and water quenching process: the crushed particles are calcined at 400-1300 ℃, and then the particles are quickly placed in an ice-water mixture for quenching for 10-20S and then washed, and then soaked in 40-50 ℃ water for 1-3min, taken out and washed with deionized water and dried.

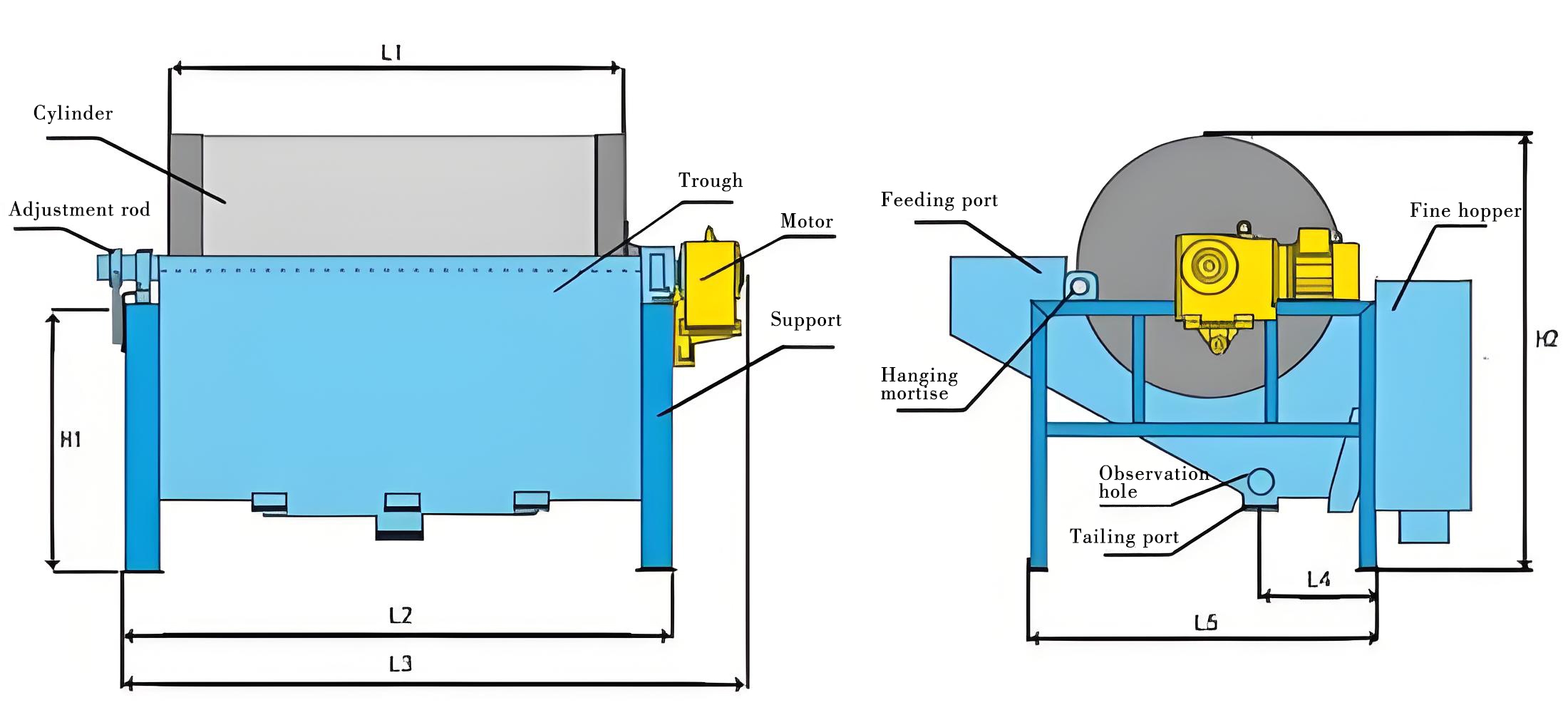

Then there is electric separation and magnetic separation: put the particles into a wet ball mill and grind them to 50-100 mesh, apply a DC electric field of 200-400v/cm at 150-250 ℃ for 1-2h, and then apply a magnetic field strength of 5000-7000GS in a magnetic separator for magnetic separation. Grind the particles after magnetic separation to 150-200 mesh again, apply a DC electric field of 500-700v/cm at a temperature of 300-450 ℃ for 0.5-1.5h, and apply a magnetic field strength of 8000-10000GS in a magnetic separator for magnetic separation again. The collected quartz sand enters the acid washing process.

Pickling treatment: Soak the quartz sand in a hydrochloric acid solution with a mass fraction of 15-25% for 1-3 hours, filter and collect the first filtrate and the filtered quartz sand, dialyze the first filtrate with an anion exchange membrane in a dialysis tank to obtain the recovered hydrochloric acid, rinse the soaked quartz sand with deionized water, add a sodium carbonate solution with a mass fraction of 4-6% and stir for 0.5-0.8 hours. The solid-liquid ratio of quartz sand to sodium carbonate is 1:1.3-1.6, and filter and rinse with deionized water after stirring.

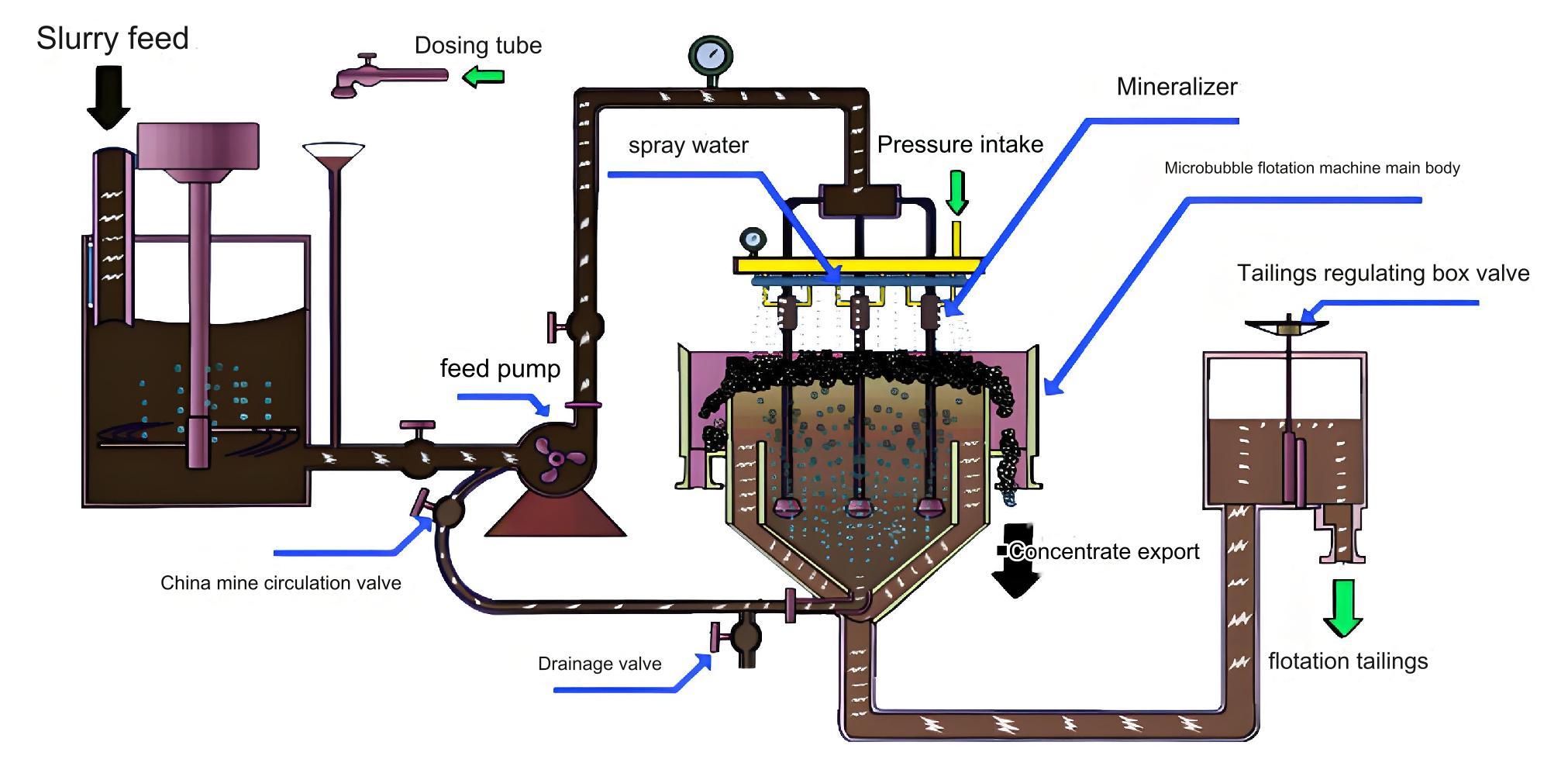

Flotation treatment: Put the rinsed quartz sand into a flotation machine for flotation, add a flotation agent and adjust the pH to 1-3 with hydrochloric acid, the flotation time is 4-6 minutes, and wash the quartz sand with deionized water to neutral after flotation.

Drying treatment: Use a dryer to dry the washed quartz sand at 200-300 ℃ for 4-10 hours, and the water content of the dried quartz sand does not exceed 0.2%.

The high-purity quartz sand obtained after the above process can meet the needs of some high-end industries.